Shop Solver

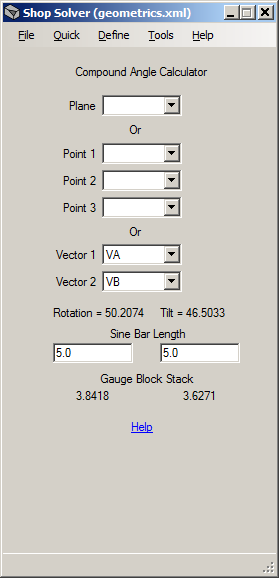

Compound Angle Calculator

Command path: Tools->Compound Angle

This tool calculates the rotation and

tilt angles required to mill a flat facet or drill a hole on

a compound angle.

The

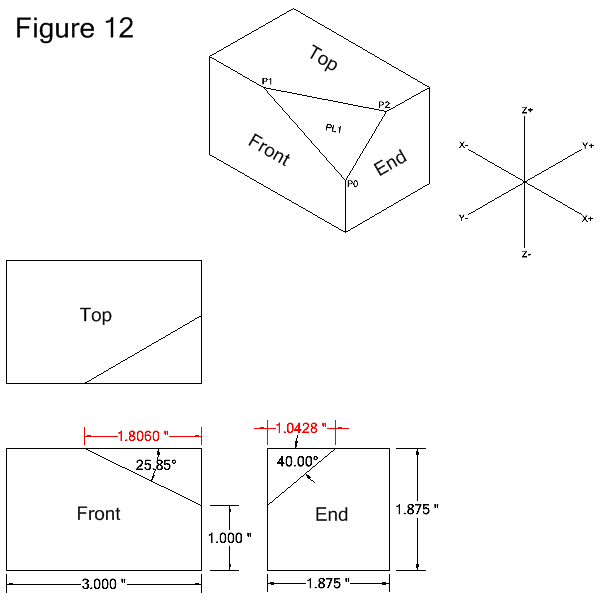

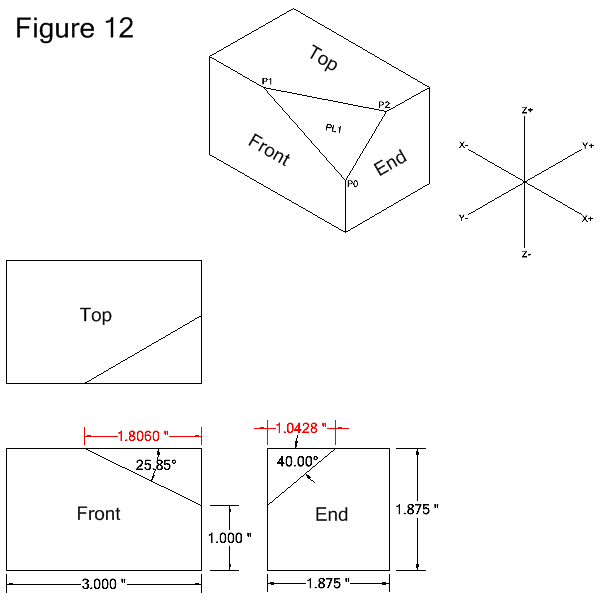

following 3 examples for milling a compound facet refer to Figure 12

below. All given dimensions are shown in black. Calculated

dimensions are shown in red. The examples assume that the facet

will be milled with the bottom of the cutter. Click here for an example for

drilling a hole on a compound angle.

Note: The Triangle Solver tool can be used to determine the calculated dimensions shown in Figure 12.

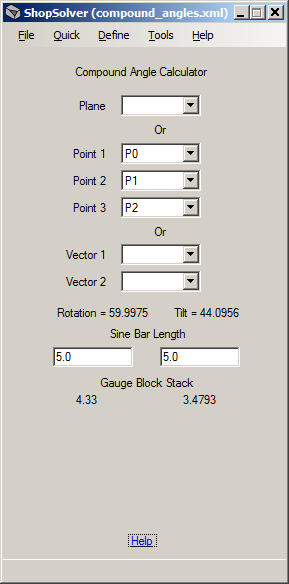

Example for milling a compound facet via a plane definition

Example for milling a compound facet via the definitions of 3 points

Example for milling a compound facet via the definitions of 2 vectors

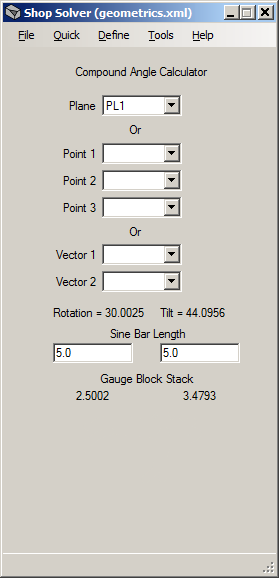

Example 1: Milling a Facet via a Plane Definition

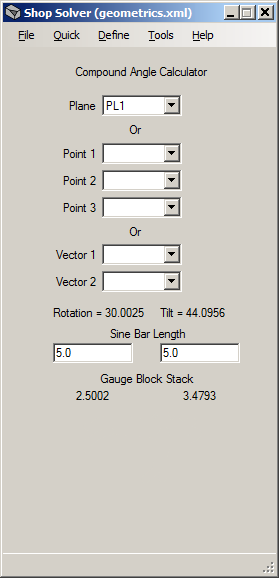

In the tool image above the plane PL1 has been selected in the Plane drop-down list. Click here

for the plane definition descriptions. In this example the plane

was defined as going through 3 nonlinear points. Figure 12 above shows

the 3 points named P0, P1 and P2. For reference the coordinates

of the 3 points are:

P0 = X0 Y0 Z0

P1 = X-1.806 Y0 Z0.875

P2 = X0 Y1.0428 Z0.875

Selecting

the plane automatically calculates the rotation and tilt angles

required to mill the facet. The angles are in degrees and are

shown below the Vector drop-down fields (see Note 1).

Gauge

block stacks for the rotation and tilt angles may be determined by

entering the lengths of the sine bars to be used. In the tool

image sine bar lengths of 5.0 were specified.

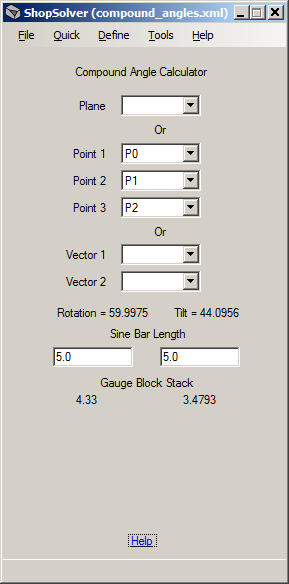

Example 2: Milling a Facet via 3 Point Defintions

In

the tool image above 3 points have been selected, each representing a

corner of the facet to be milled. Click here

for the point definition descriptions. Figure 12 above shows

the 3 points named P0, P1 and P2. For reference the coordinates

of the 3 points are:

P0 = X0 Y0 Z0

P1 = X-1.806 Y0 Z0.875

P2 = X0 Y1.0428 Z0.875

When all 3 points have been selected the tool automatically calculates the rotation and tilt angles

required to mill the facet. The angles are in degrees and are

shown below the Vector drop-down fields (see Note 1).

Gauge

block stacks for the rotation and tilt angles may be determined by

entering the lengths of the sine bars to be used. In the tool

image sine bar lengths of 5.0 were specified.

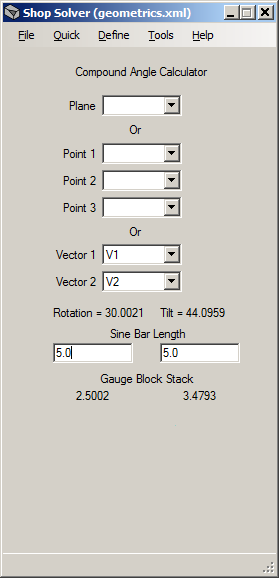

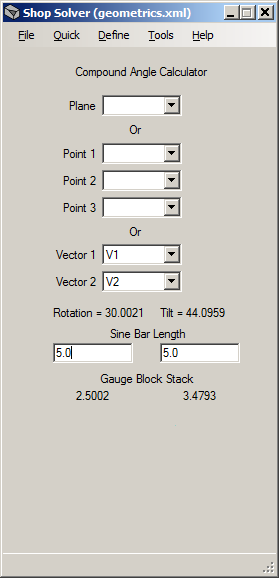

Example 3: Milling a Facet via 2 Vector Defintions

In the tool image above, 2 vectors have been selected. Click here

for the vector definition descriptions. Each

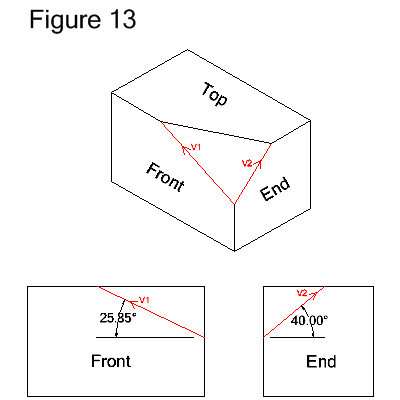

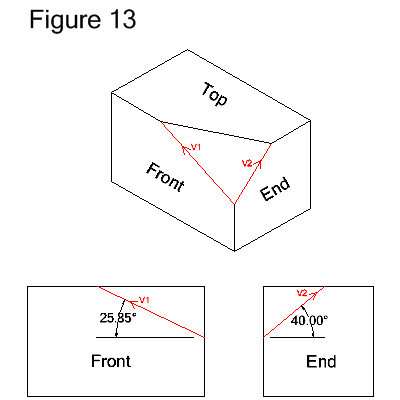

vector represents an edge on the facet. Figure 13 below shows the 2

vectors, named V1 and V2, in red. The vectors are defined as

"Length (Magnitude) and an Angle in a Plane". For reference the

vector definitions are:

V1=VECTOR/LENGTH,1.0,ATANGL,25.85,ZXPLAN

V2=VECTOR/LENGTH,1.0,ATANGL,40.0,YZPLAN

The vector properties are:

- The length of both vectors is 1.0. The lengths are not important -- they just need to be greater than zero.

- V1 is defined in the ZX plane at an angle of 25.85 degrees.

- V2 is defined in the YZ plane at an angle of 40.0 degrees.

Note: Any 2 edges

of the facet may be used. For example:

V3=VECTOR/LENGTH,1.0,ATANGL,-154.15,ZXPLAN $$ complement of angle of V1 (front view)

V4=VECTOR/LENGTH,1.0,ATANGL,30.0,XYPLAN $$ angle when looking down at top view

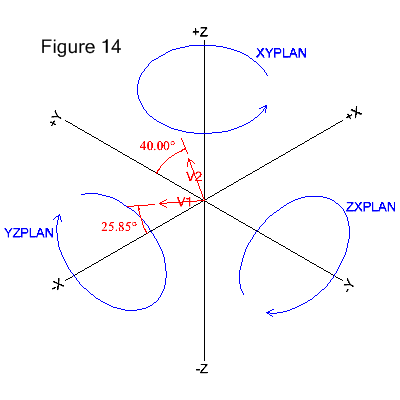

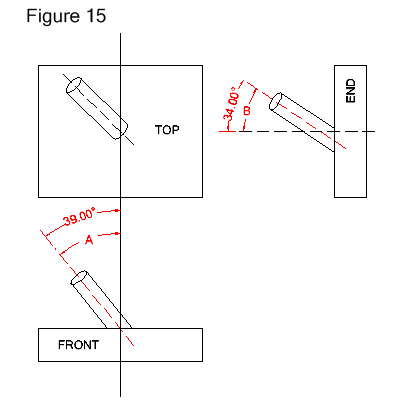

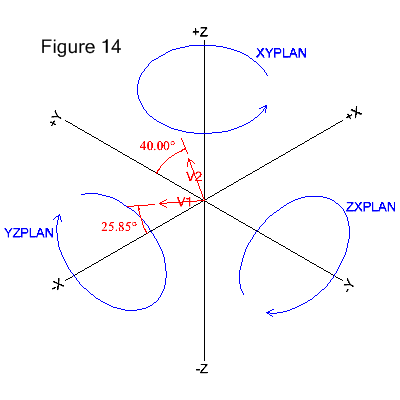

Figure

14 below depicts another representation of vectors V1 and V2. The blue circles

show the direction of positive angles around their respective axes.

Positive angles are counter-clockwise and determined by looking

along an axis from the positive end toward the origin. Zero

degrees is at 3 o'clock when looking along an axis.

When both vectors have been selected the tool automatically calculates the rotation and tilt angles

required to mill the facet. The angles are in degrees and are

shown below the Vector drop-down fields (see Note 1).

Gauge

block stacks for the rotation and tilt angles may be determined by

entering the lengths of the sine bars to be used. In the tool

image sine bar lengths of 5.0 were specified.

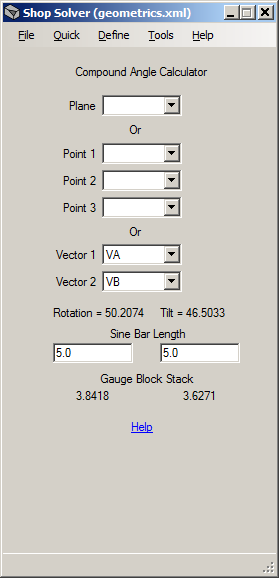

Example 4: Drilling a Hole via 2 Vector Definitions

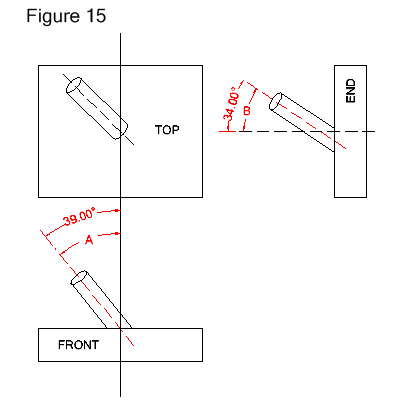

In

the tool image above, 2 vectors have been selected. The vectors

represent the angles of a cylinder's centerline, as shown in Figure 15 below.

(Click here

for the vector definition descriptions.) The

vectors, named VA and VB, are associated with angles "A" and "B".

The vectors' angles are those required to rotate the cylinder

into a vertical position. Note: The angles are not the

compound angles required to drill the hole, just the values given on the print or in

the specification.

In Figure 15 below, VA must be rotated 39.0 degrees

in the ZX plane to become vertical. VB must be rotated 34.0

degrees in the YZ plane to become vertical. Refer to Figure 14 above for how to determine direction of rotation. Both vectors are defined as

"Length (Magnitude) and an Angle in a Plane". For reference the

vector definitions are:

VA=VECTOR/LENGTH,1.0,ATANGL,39.0,ZXPLAN

VB=VECTOR/LENGTH,1.0,ATANGL,34.0,YZPLAN

The vector properties are:

- The length of both vectors is 1.0. The lengths are not important -- they just need to be greater than zero.

- VA is defined in the ZX plane at an angle of 39.0 degrees.

- VB is defined in the YZ plane at an angle of 34.0 degrees.

When both vectors have been selected the tool automatically calculates the rotation and tilt angles

required to drill the hole. The angles are in degrees and are

shown below the Vector drop-down fields (see Note 1).

Gauge

block stacks for the rotation and tilt angles may be determined by

entering the lengths of the sine bars to be used. In the tool

image sine bar lengths of 5.0 were specified.

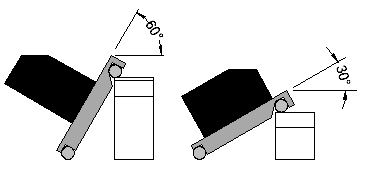

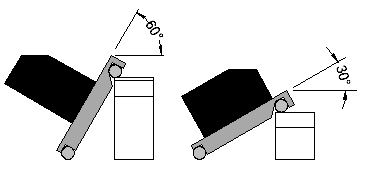

Note 1

Depending upon the set-up, it may be

necessary to calculate and use the complement of an angle, especially if the required sine bar angle is greater than 45 degrees.

This is because the gauge block stack required to obtain the

angle may be too great for setting the sine bar. Therefore the

angle of the sine bar and the part surface contacting the sine bar must

be altered. An example is shown below. On the left the part

to be milled is resting on its narrow width causing the angle of the

sine bar to be too steep. On the right the part is resting on its

length and the angle of the sine bar is acceptable. Again,

depending upon the set-up, this may need to be applied to either the

tilt or rotation angle.