Shop Solver

3-Pin Bore Calculator

Command path: Tools->3-Pin Bore Calculator

This tool provides the following features:

- Calculates the diameters of 3 equally sized gage pins that will fit into a bore of a given diameter.

Use this as a starting point for determining the diameters of 3

gage pins of different diameters that fit into a bore that you need to

measure.

- Calculates the diameter of a bore given the diameters of 3 gage pins.

- Calculates the diameter of a third gage pin given the diameter of a bore and 2 gage pins.

- Determines when 3 gage pins touch their circumscribed bore so as to provide a tight and accurate fit.

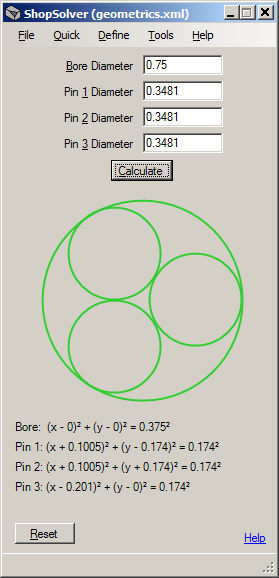

Calculate the Diameter of 3 Equally Sized Gage Pins for a Given Bore Diameter

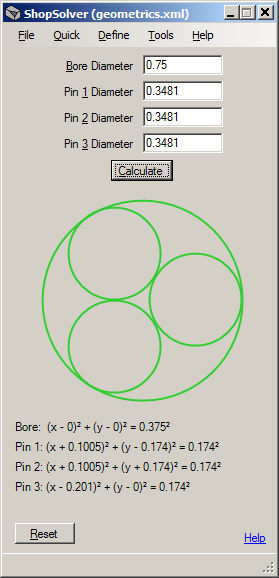

The image below shows the diameters of 3 gage pins of equal size that fit into a bore of 0.75.

To determine the diameters of 3 equally sized gage pins that fit into a bore of a given diameter:

- Click the Reset button to reset all fields.

- Enter the bore diameter.

- Click the Calculate button.

Use

the calculated gage pin diameters as a starting point for 3 pins needed

to check your bore diameter. See the description for calculating

the diameter of a third gage pin below.

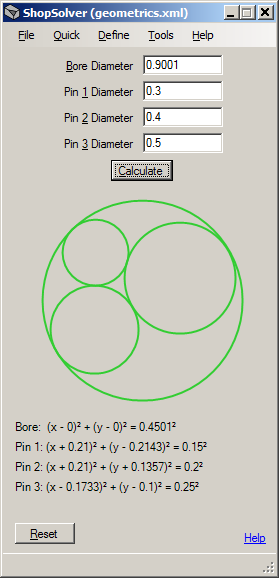

Calculate the Diameter of a Bore Given the Diameters of 3 Gage Pins

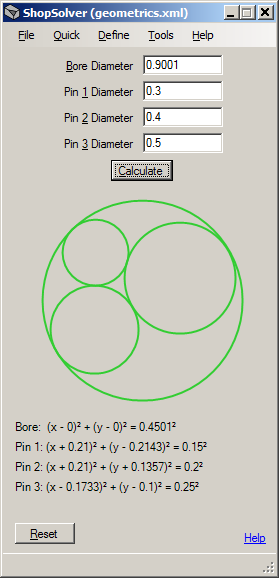

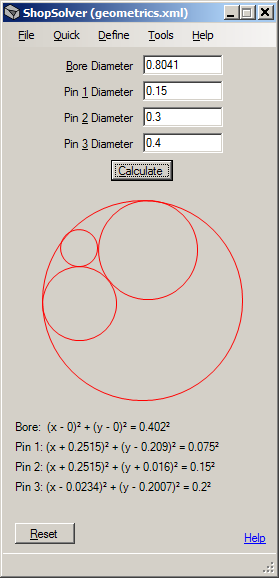

The image below shows the calculation of a bore diameter from the diameters of 3 gage pins.

To determine the diameter of a bore from the diameters of 3 gage pins:

- Click the Reset button to reset all fields.

- Clear the value in the Bore Diameter field.

- Enter the diameters of the 3 gage pins.

- Click the Calculate button.

In the sample image above 3 gage pins of diameters 0.3, 0.4 and 0.5 were given. The calculated bore diameter is 0.9001.

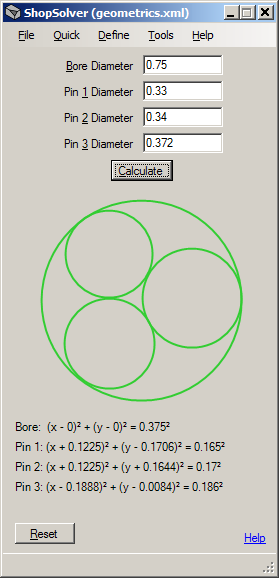

Calculate the Diameter of a Third Gage Pin Given the Diameter of a Bore and 2 Gage Pins

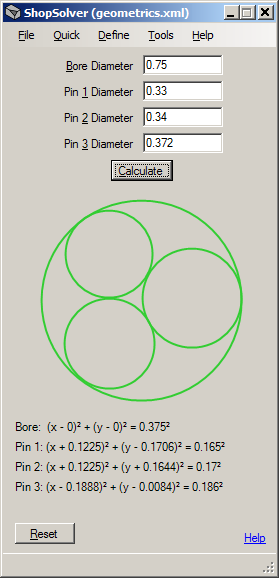

The

image below shows the calculation of a third gage pin given a bore

diameter of 0.75 and 2 gage pins of diameters 0.33 and 0.34.

To determine the diameter of a third gage pin:

- Click the Reset button to reset all fields.

- Enter the bore diameter in the Bore Diameter field.

- Enter diameters in the Pin 1 Diameter and Pin 2 Diameter fields.

- Click the Calculate button.

In

the sample image above a bore diameter of 0.75 was given as were 2 gage

pin diameters of 0.33 and 0.34. The calculated diameter of the

third pin is 0.372.

Hint:

Use the calculator to determine the diameter of 3 equally sized

gage pins (described above). Then, for pin 2, enter a diameter

smaller by as little as 1 or 2 thousandths and let the calculator

determine the diameter of the third pin. That will insure a good fit of the pins in the bore as described below.

Determining Proper Gage Pin Contact Points for Accuracy

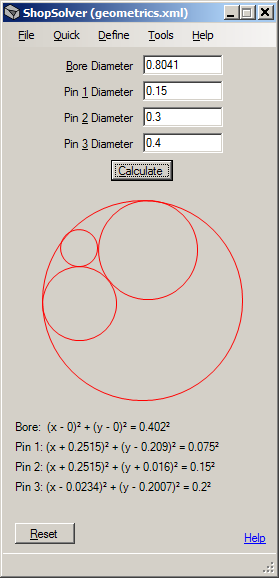

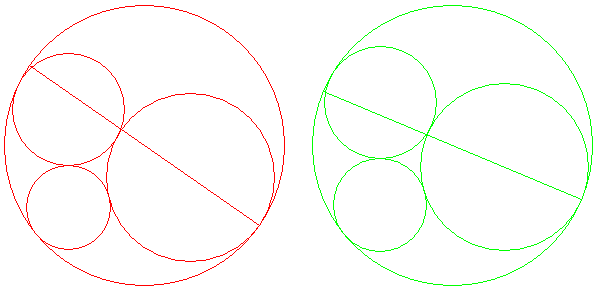

This

tool uses mathematics developed by Rene Descartes to calculate the

circle that circumscribes 3 mutually tangent circles. However,

there is no guarantee that the 3 circles contact the outer circle such

that they fit properly and accurately into it. An example is

shown below.

The

example shows 3 gage pin diameters of 0.15, 0.3 and 0.4 and the

calculated bore diameter of 0.8041. As can be seen the 3 gage

pins do not provide a tight and accurate fit within the bore. In

order to fit properly within a bore the 3 gage pins must contact the

bore in the 2 hemispheres determined by a line drawn through the center

of the largest gage pin where it is tangent to the bore. That is,

the points where the 2 smaller gage pins contact the bore must be on

opposite sides of the line. The following images better

illustrate this.

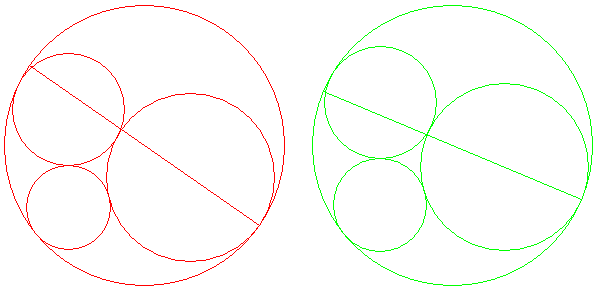

The

red image shows that both of the 2 smaller gage pins contact the bore

on the same side of the line that bisects the large gage pin.

When that is the case the fit of the pins in the bore is sloppy

and the tool draws the image in red. The green image shows that

the 2 smaller gage pins contact the bore on opposite sides of the line.

When that is the case the 3 gage pins properly contact the bore

and will provide an accurate measurement and the tool draws the image

in green.

For

the benefit of geometry students and math hounds in general, the

equations of the 4 circles are shown at the bottom of the tool.