Shop Solver

Thread Reference

Command path: Tools->Thread Reference

This

tool calculates the dimensions of imperial Unified National and metric

ISO M-series thread form properties such as major, minor and pitch

diameters, compound depth of cut (note 1) and best wire size. Standard and non-standard thread forms are supported (note 2).

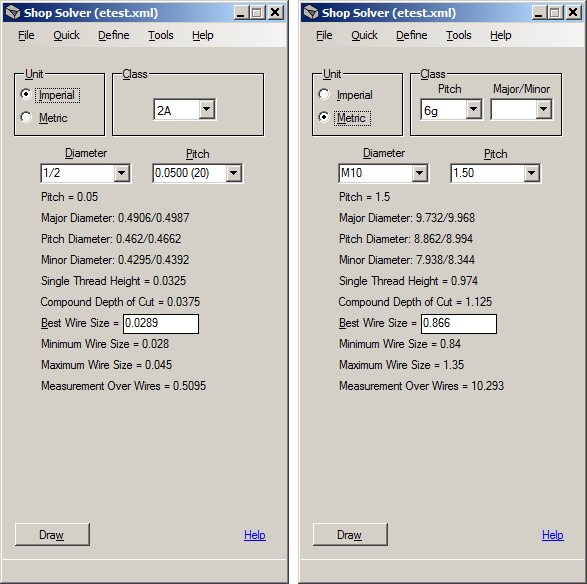

Tool Images

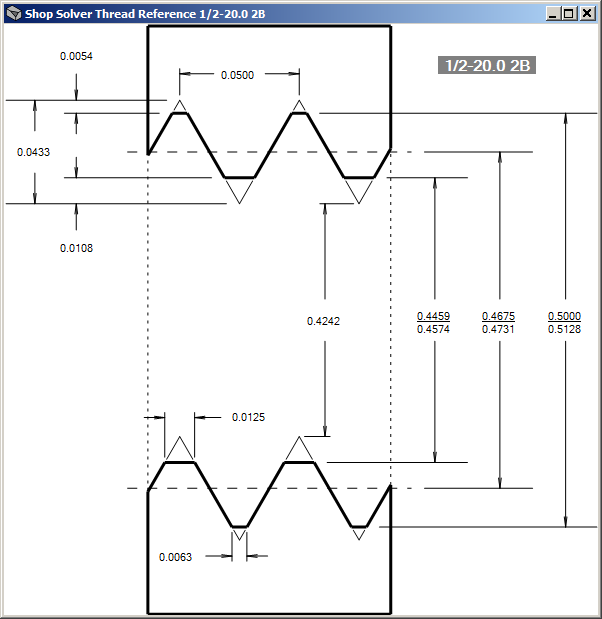

Imperial

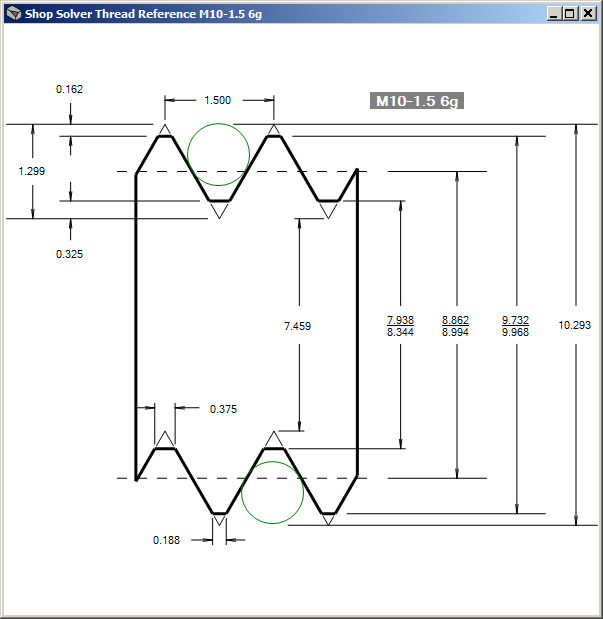

Metric

To determine the properties for a thread form:

1) Select the desired unit of measurement (imperial or metric) from the provided radio buttons.

2) Select the thread class in the Class drop down. Click here for a short overview about thread classes.

3) Select the thread diameter in the Diameter drop down. If the desired diameter is not listed you may enter the diameter directly into the text field:

- Imperial wire sizes must be prefaced with "#". Example: For wire size 15 (non-standard) enter "#15" (no quotes).

- Fractional diameters may be entered directly. Example: 27/64

- Decimal diameters may be entered directly or as any valid mathematical expression. Example: 0.4219.

- Metric

decimal diameters may be entered directly and may be prefaced with an

upper case or lower case "M". Example: 1.6 or M1.6.

Note: To use a mathematical expression do not preface it

with an "M".

4) Select the thread pitch in the Pitch drop down. The Pitch

drop down is automatically populated with values commonly associated

with the selected diameter. If the desired pitch is not listed

you may enter the pitch as a decimal value or as a fraction (or as any

valid mathematical expression) directly into the text field:

- Imperial pitches are commonly expressed as Threads per Inch (TPI).

However, the pitch field requires a decimal value. To

convert TPI to a decimal value enter the pitch as a fraction.

Example: 13.5 TPI (non-standard) should be entered as

"1/13.5" (no quotes).

- Metric pitches may be entered as a decimal value or any valid mathematical expression.

The thread form properties shown below the Diameter and Pitch

drop downs are updated automatically whenever a new unit or thread

class is selected, and whenever you tab between fields or press Enter.

Best Wire Size

The

best wire size (BWS) is automatically calculated for external thread

forms. In addition the measurement over the wires and the minimum

and maximum wire sizes are also calculated.

A custom wire size may be specified by entering its diameter in the Best Wire Size text field. Pressing TAB or Enter will recalculate the Measurement Over Wires value.

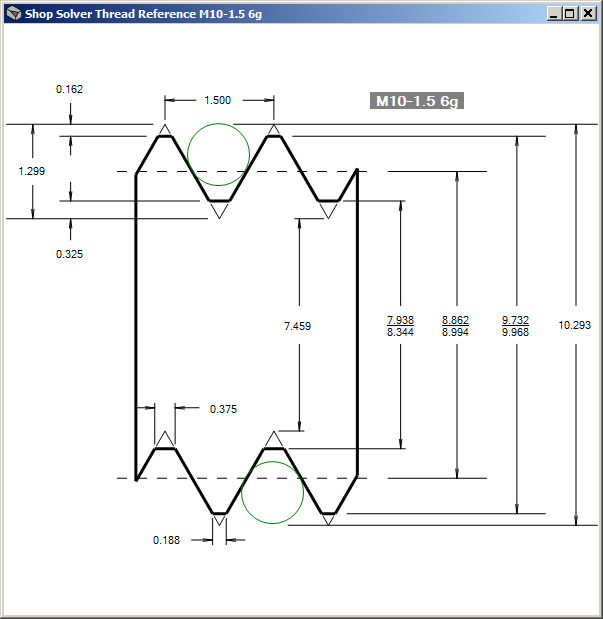

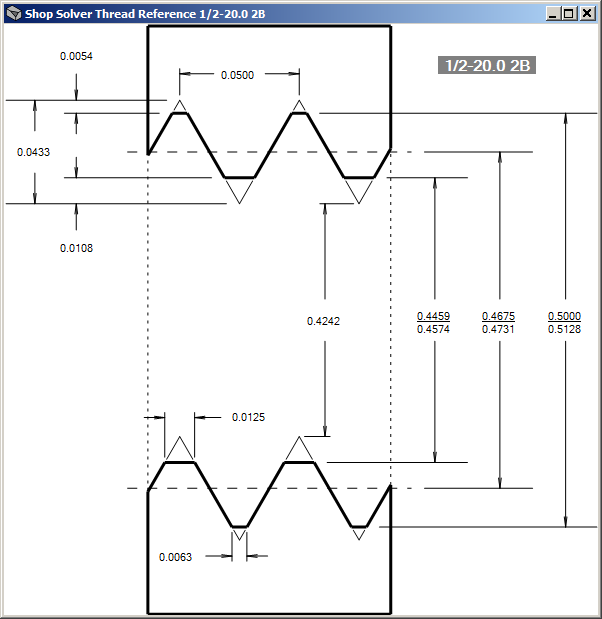

Drawing the Thread Image

Click the Draw

button to view an image of the currently defined thread. A

dashed line in the image denotes the pitch diameter values. Green

circles denote wires used for measuring external threads.

Examples are shown below.

To save a thread image to a file, right click on the image and select "Save As File..." in the pop-up menu. A Save As File

dialog will be displayed where the name and location of the file and

the image type can be specified. When the file save is complete

the image is displayed in the default image viewer.

External Thread

Internal Thread

Thread Classes

Imperial

- Classes 1A, 2A and 3A apply to external threads. Classes 1B, 2B and 3B apply to internal threads.

- Class 1 designates the loosest fit.

- Class 2 designates the typical, most common, fit.

- Class 3 designates the most precise fit.

Metric

The screw thread designation M10x1.25-4g6g is used as a reference.

- "4g6g" is the thread tolerance class.

- "4g" is the thread pitch tolerance class designation.

- "6g" is the thread major tolerance class designation.

- "4" and "6" are the tolerance grades and are applied to both external and internal threads.

Smaller numbers designate tighter tolerances and higher numbers

designate looser tolerances.

- The

letters are the tolerance positions. Lower case letters designate

external threads and upper case letters designate internal threads.

- It is the custom to not repeat the class

designation if the pitch and major/minor tolerances are the same.

For example, tolerance class "6g6g" may be specified as "6g".

Notes

- The

Compound Depth of Cut is the approximate total depth of cut for 60 degree threads when the compound is set to 29.5 degrees.

- This

tool allows the user to specify non-standard thread form properties.

Therefore, the user can select and enter any thread property

values they like. Care must be taken when selecting or entering

property values to ensure accurate results.

"Garbage in, garbage out."