Jan 29, 2020

New:

CYCLE/TURN lathe post-processor command for OD and ID rough stock

removal. Similar to the G71 command provided by some CNC lathe

controllers, this automatically generates the rough turning passes

needed to remove excess stock during turning and boring operations.

See the post-processor documentation for the CYCLE command for a full description.

Jan 21, 2020

Recently added: LETTER post-processor command: Mill/engrave alphanumeric strings.

Jan 12, 2020

If anyone would like to try any of the following applications, contact me at aptfan@frenetec.com.

All I ask is that you let me know about any bugs/problems and

suggestions for improvement. The post-processor currently

supports mills and lathes for the Centroid, Fanuc, Haas and Tormach

controllers. Follow the links below to browse the

applications' documentation.

APT360 pre-processor

APT360 post-processor

Post-processor options file

NC plotter

APT source file template

APT command file

I

can also provide a copy of the APT360 compiler (apt360.exe for Windows) if

you need it. I built if from the free source code as described

earlier (see https://sourceforge.net/p/aptos/apt360/ci/master/tree) and fixed a bug pertaining to defining a point as a location in a PATERN.

The editor is not ready for public consumption.

Jan 11, 2020

TRACUT and COPY cutter location transformations are stored in the

"enhanced" binary cutter location file PRO.TAP (along with all other

cutter location records). If your APT program uses either TRACUT

or COPY you must post-process the file PRO.TAP rather than CL.TAP.

To determine which file to post-process just scan either

CL.TAP or PRO.TAP for TRACUT and COPY record types (see below for the

record type definition). If the scanned file contains either

record then PRO.TAP must be used. Technically TRACUT and COPY are post-processor commands so you

can use CL.TAP if you provide your own implementations.

Sep 24, 2019

I

have been sidetracked by other projects so it has been a while.

Something I have been meaning to do is document the record

structure of the APT360 binary cutter location file, CL.TAP.

Hopefully

this information will be of help to anyone wishing to write their own

post-processor. Note: This information is for the Windows

platform and is the best of my knowledge up to this date. It is

not exhaustive as I certainly have not tested every feature of the APT

language. Please contact me if anything is incorrect, has

been omitted, or if something could use further explanation.

Each record begins with a block that identifies and

describes the record. Following the block is the data associated

with the record. This pattern repeats for the rest of the records

in the file. The structure of the block is as follows:

RECNO (4-byte integer): This record's record number.

COUNT (4-byte integer): Count of 8 byte entries in this record's data (8 * count = the length of the data in bytes).

RECTYPE (4-byte integer): The record type.

SUBTYPE (4-byte integer): The record subtype.

DATA (8 * count bytes): The record's data.

The record types (RECTYPE) that I have discovered are:

1000:

The record number (RECNO in the CLPRNT file) and the Input Sequence

Number (ISN). The ISN is in the SUBTYPE field. All other

record types are preceded by a 1000 record. Hint: Every APT

program line can be identified by its ISN number in the CLPRNT file.

2000:

Post-processor commands. The specific command is in the

SUBTYPE field. The record's DATA is formatted to match the

commands' parameters which, in turn, are specific to the

post-processor implementation. As such, I cannot document each

command here. Suffice it to say that the data can contain bytes

that are characters, integers mapped to APT minor words, and Doubles.

3000:

I believe this describes any nested surface definitions such as

LINE, CIRCLE, etc. SUBTYPE is either not used or I have not

determined how it is used. The specific surface type is

identified by a 4-byte integer beginning at byte 8 in the DATA.

The surface's name is in bytes 24-31. The subscript used

with the surface's name is a double-precision floating point number

(i.e. a Double) at byte 32. The remainder of the data are Doubles

and are the canonical values of the specific surface type.

4000: Unknown

5000:

For lack of a better description this is an actual cutter

location record. SUBTYPE identifies the source of the cutter

location. So far I have discovered SUBTYPEs: FROM

(3), GODLTA (4), GOTO (5) and SRFCNTD (6). The DATA may

contain a surface name, subscript, point coordinates and tool axis

vectors.

6000:

I believe this describes DNTCUT/CUT (SUBTYPE=1) and OUTTOL/INTOL

commands (SUBTYPEs 4 and 5), and cutter shape definition data (6).

7000: Unknown

8000: Unknown

9000: So far this looks like a MULTAX record when SUBTYPE=2. ON or OFF is a 4-byte integer at byte 0 in the DATA.

13000:

So far I have discovered 2 uses: SUBTYPE=3 is a

warning/error, although I don't follow the when's and why's of their

usage. SUBTYPE=4 is a CLPRNT and the 4-byte integer at byte 0 of

the DATA identifies the option value, if any.

14000: The FINI record.

As for the APT vocabulary, post-processor words and their values can be found here. Minor words and their values can be found here.

Jan 31, 2018

I

got sidetracked on the above when I began reviewing my implementation

of some of the post-processor words I have implemented. For

example I went too far with the CLEARP implementation and decided to

align it with Irvin Kral's definition. In short he defined it as

specifying a plane parallel only with the XY plane, relegating it

effective only to the Z-axis. As a result my post-processor now

supports RETRCT for a mill only.

I also reviewed my planned

implementation of the CLRSRF command. The documentation does not

specify what it should do and Irvin Kral does not cover it in his book

so I'm wondering if anyone has any input on the subject. Should

it just rapid to the specified surface using the shortest distance from

the current cutter location? Does anyone think it is a "must

have" option?

Jan 26, 2018

For

the past few days I have been attempting to learn how to get web

crawlers to index this page and re-index it regularly. It seems

to me that those in control of such matters are constantly changing the rules.

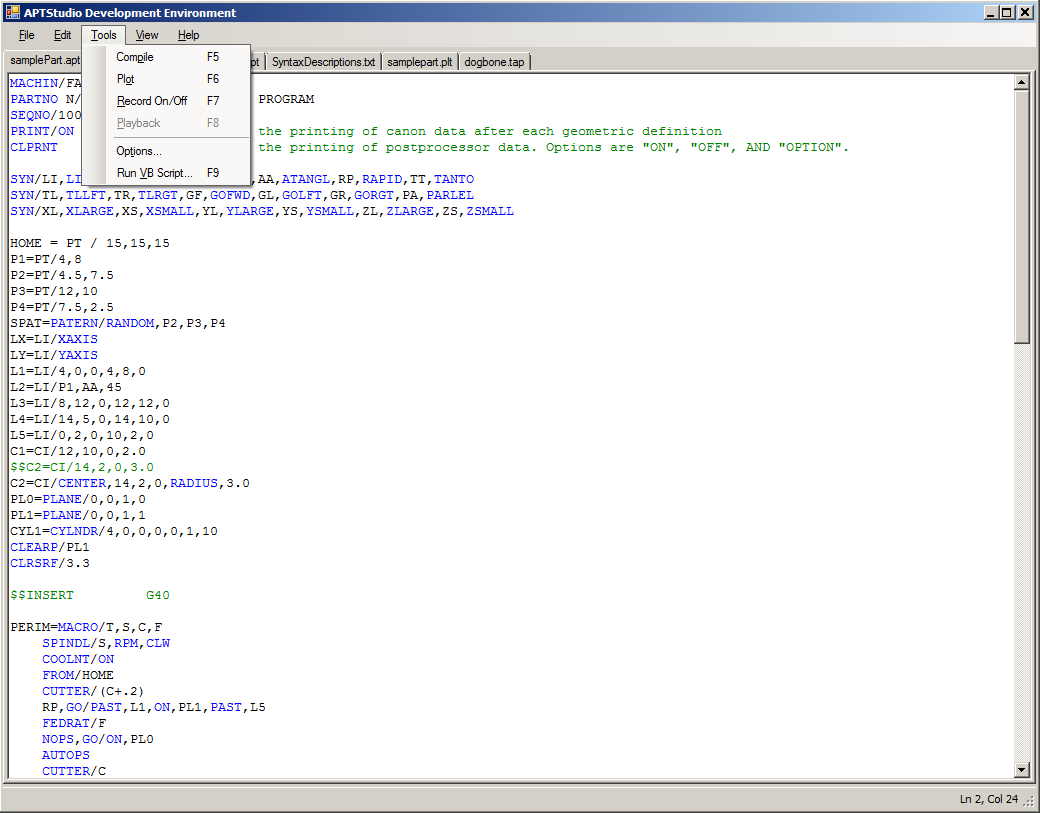

Today

I started the design of (for lack of better terminology) the

"Post-processor Vocabulary Word Assistant." Similar to the

Geometric Definition Assistant it will provide syntax help for

post-processor words with parameters. For example, when "COOLNT/"

is typed a window will pop up and display the syntax of the coolant

command and the parameters that the post-processor supports, such as

"ON" and "OFF". As another example typing "CYCLE/" will display

the syntax of the various cycle commands (such as drill, tap, etc.) and

their parameters.

Jan 19, 2018

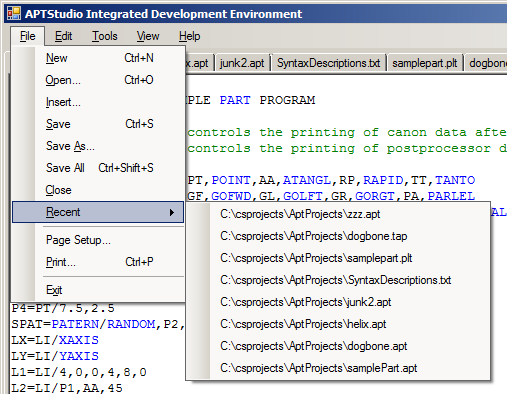

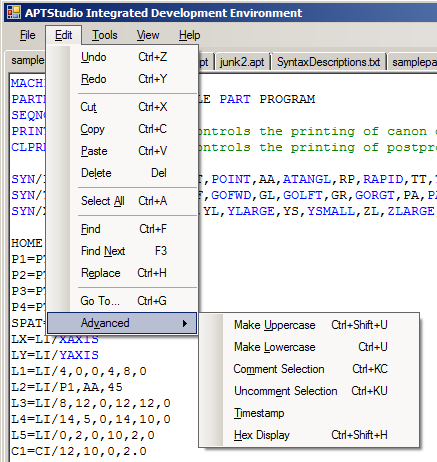

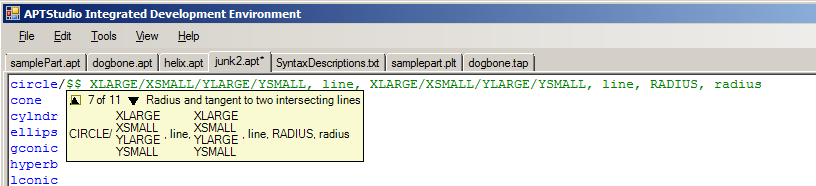

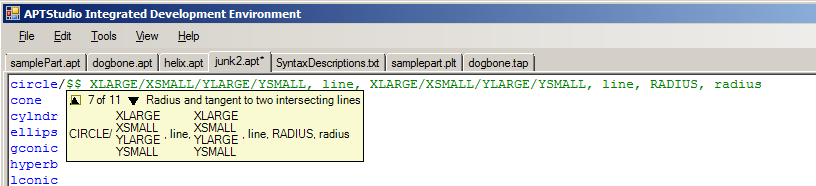

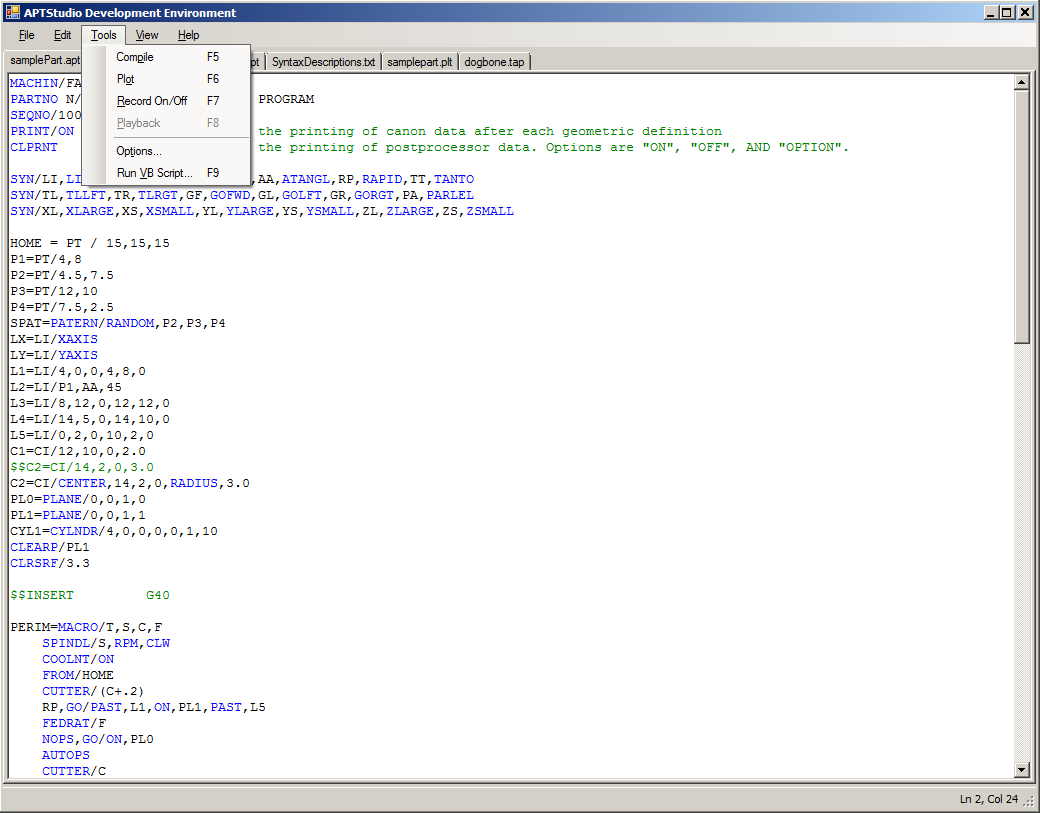

More screen shots of some of the editor features:

This

last image shows the Geometric Definition Assistant. It pops up

whenever a geometric definition is typed and is followed by a forward

slash. In this image "circle/" was typed and the user can select

one of the eleven possible circle definitions. Click the up and

down arrows or use the up and down arrow keys on the keyboard to

iterate through the possible definitions. Pressing the TAB

key inserts text which is a commented template for that definition.

Jan 17, 2018

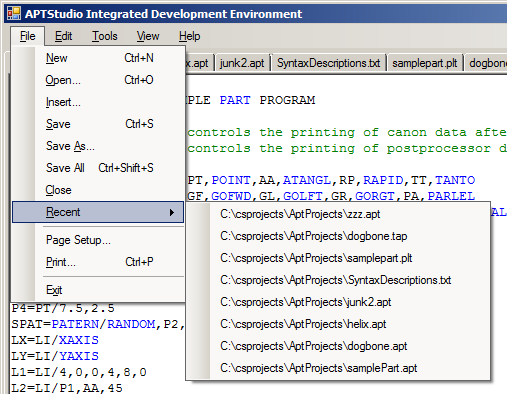

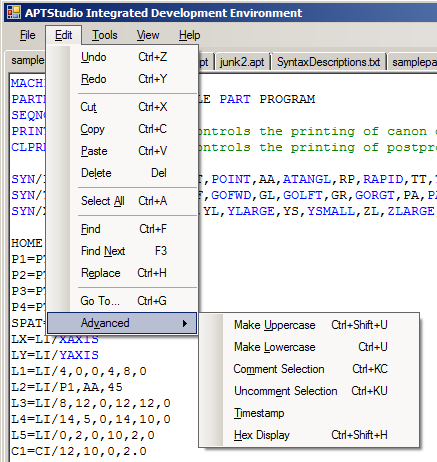

APT

Studio is an integrated development environment for creating,

compiling, post-processing and plotting APT programs. Some of the

features are:

- Editor:

multi-tabbed, syntax highlighting, geometric definition

assistant, run VB scripts, record and playback keystrokes, compile and

plot

- Post-processor:

4-axis mill, 2-axis lathe, virtual machine definitions (not user

accessible), user specified options (text file), tape and plot file

generation

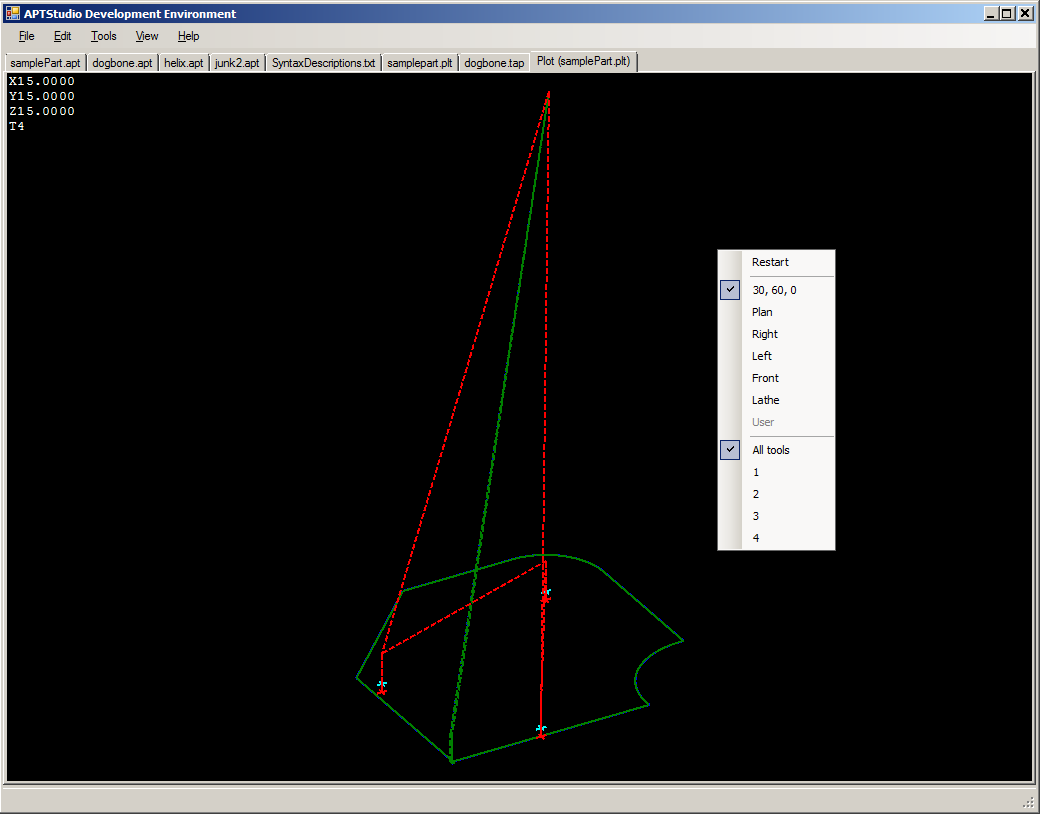

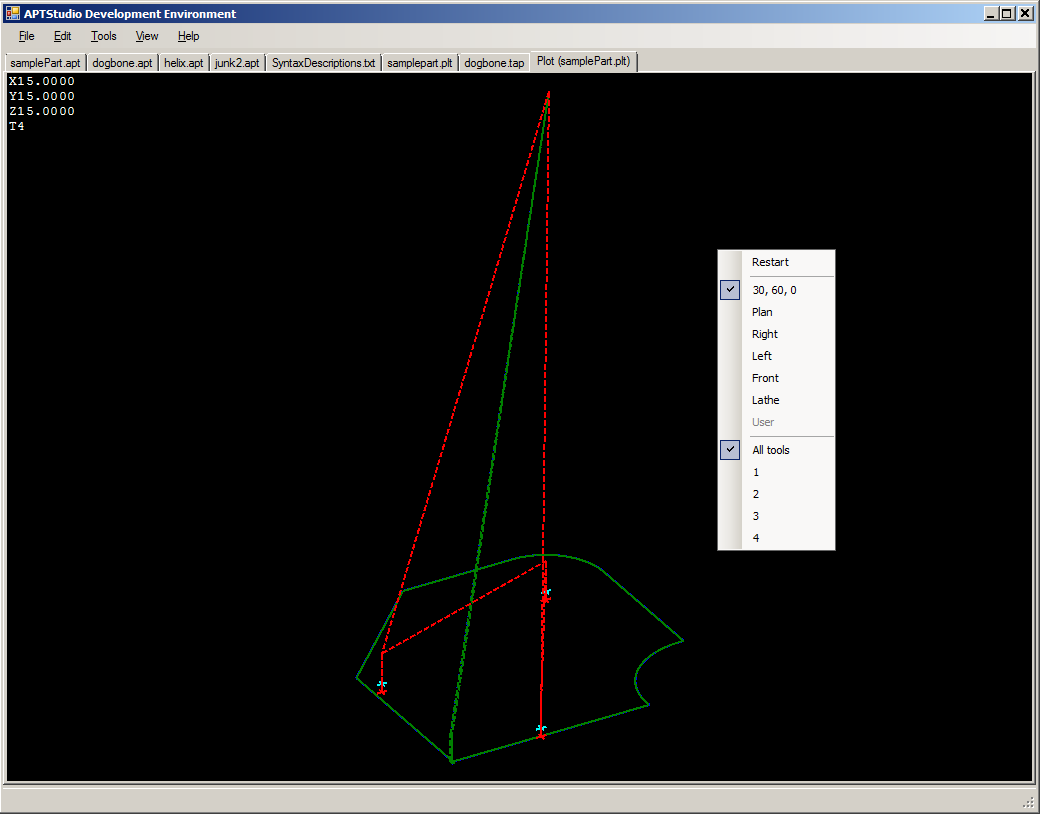

- Plotter:

3D multi-color line plotter (3-axis), plot stop/opstop to stop/opstop,

single step forward and reverse, zoom in/out, rotate about 3 axes, XYZ

cutter location and tool number, multiple predefined view angles, plot

a single tool or all tools, plot post-processor generated plot file or

existing tape files

Here's a couple of screen shots of the integrated editor and plotter:

Jan 16, 2018

Welcome to

my APT home page! Here I, and hopefully other APT fans, will

discuss all things APT. I will also talk about some of the APT related

projects I have been working on the past few months. I'm just

getting started so relax and check back occasionally. Please feel

free to contact me at aptfan@frenetec.com.

But

first, what is APT? APT is an acronym for Automatically

Programmed Tool, or some variant thereof. It is a computer

language for programming Numerically Controlled (NC) machine tools and

other devices. If I remember my history correctly, the project

began in the 1950's as a joint effort between MIT and the Air Force to

help solve the complexities of programming the newly burgeoning

industry of computer controlled machine tools, otherwise known as NC

machine tools.

I have been amazed by what APT can accomplish

ever since my introduction to NC back in the mid 1970's. My first

career was as a machinist for Texas Instruments. I worked in the

Short Order and Non-metallic shops where I was assigned to change part

stock and push the buttons on an old 2 1/2 axis Cincinnati milling

machine. If you happen to remember machines that old you will

recall that the Z-axis was controlled via cams and set screws.

Also, the floor mounted controller read a punched tape that fed through the

tape reader and rolled up on wheels behind a clear polycarbonate door

on the front of the controller. Eventually I was one of the group

programming the shop's newer CNC tools. I have always been

grateful that TI gave me the opportunity to expand my skill set as both

a machinist and APT programmer. That's where I fell in love with

programming in general and have been doing so ever since.

So why

this web page dedicated to APT? I feel that it is worth paying

homage to such a great technological leap forward at a time when

manufacturing industrial might and computers were being integrated, all

right here in the great country of the USA. I also fear that APT

programming and programmers are being forgotten and that such valuable

skills and resources will be lost with the passage of time. CAM

is the reigning king today as the industry has taken mighty

technological leaps forward. APT may be a dinosaur but it is

still around, doing all sorts of amazing calculations

and helping to machine amazing parts on even more amazing tools.

I

wish to express my thanks to the group of individuals that ported the

IBM 360 version of APT to Unix and Windows. I obtained the freely

distributable source code (a project entitled "Aptos", which is available for download at https://sourceforge.net/p/aptos/apt360/ci/master/tree)

and compiled it with Microsoft's Visual Studio Express 2015. As I

recall I had to tweak a couple of headers and fixed a bug related to

defining a point as a member of a pattern, but so far I've had good

luck with the port. I have not pushed the code to its limits by

any means, as I've been busy with developing projects related to making

it easier to use, but so far it seems to work very well. There

are a couple of known issues with it, which are are documented in the

README file included with the source code, but I have not found them to

be an impediment. So

thanks Aptos folks for your hard work and dedication to APT!

Up

to this point I have written a post-processor targeting Fanuc

controllers for

mills and lathes, a synonym parser (because the APT port does not

support synonyms), an editor and a 3D line plotter. My target

environment is Microsoft Windows and all coding is done in C#.

Update: The post-processor now additionally supports Centroid M-Series mill and T-Series lathe.